WHAT WE DO

-

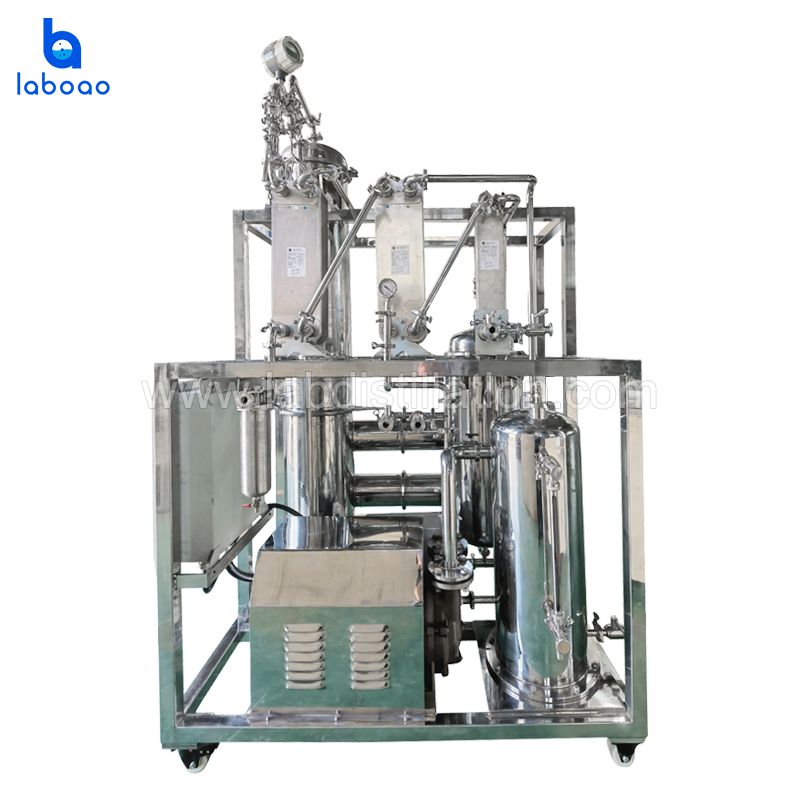

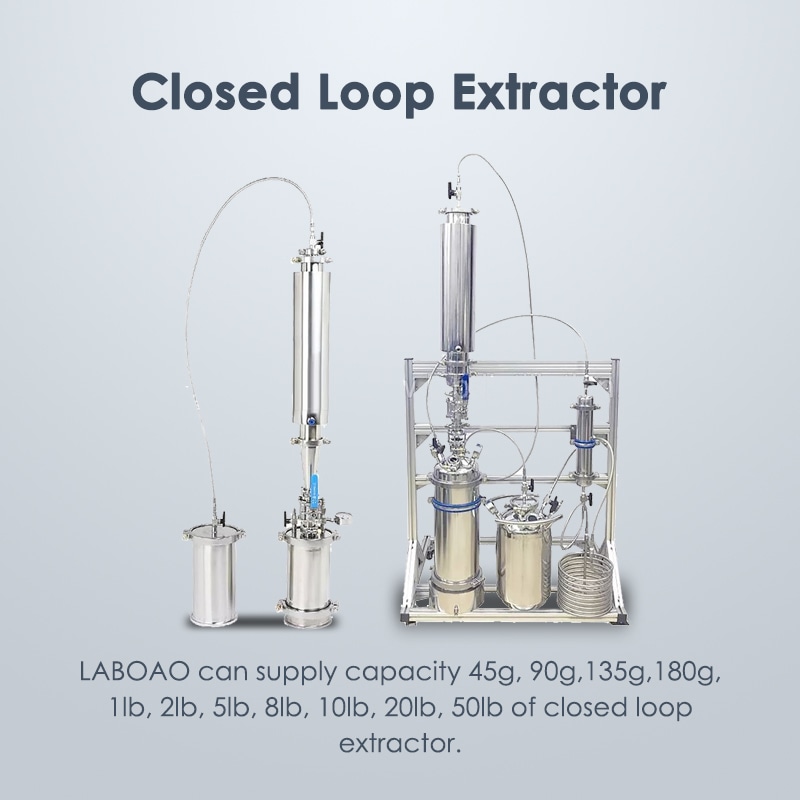

Closed Loop Extractor

-

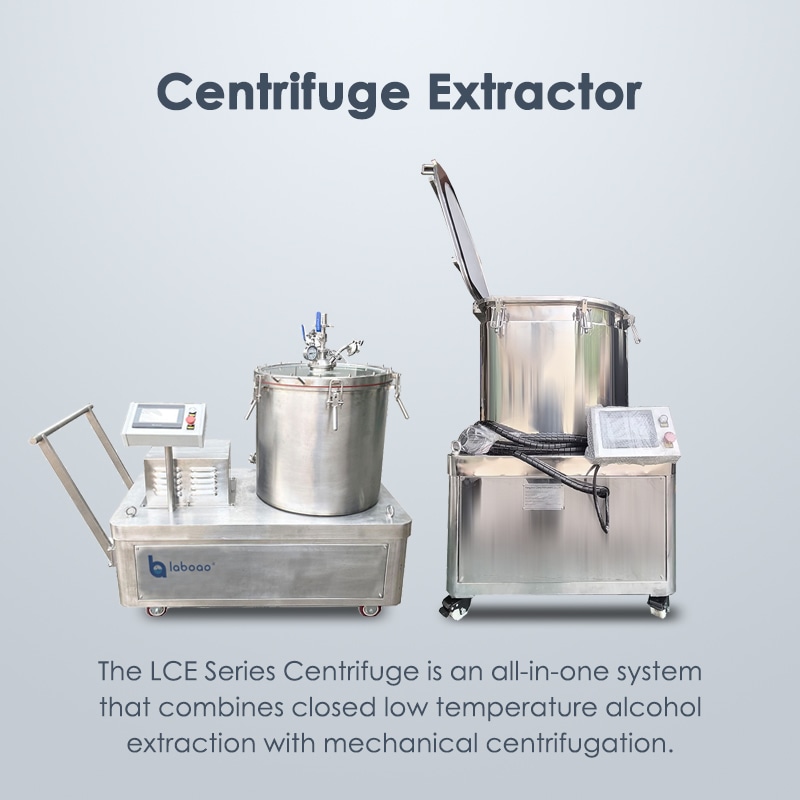

Centrifuge Extractor

-

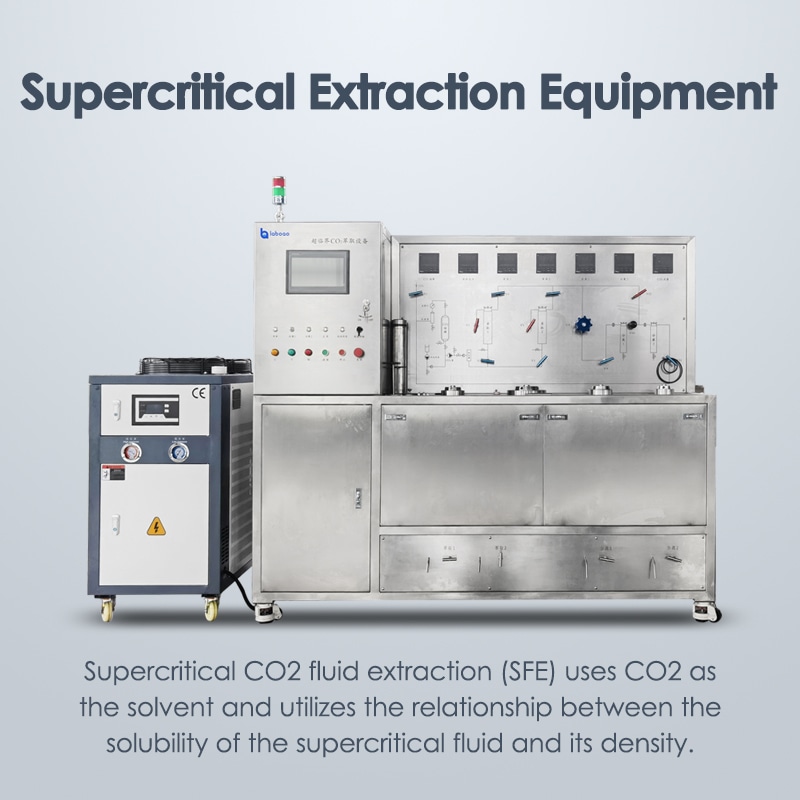

Supercritical Extraction Equipment

-

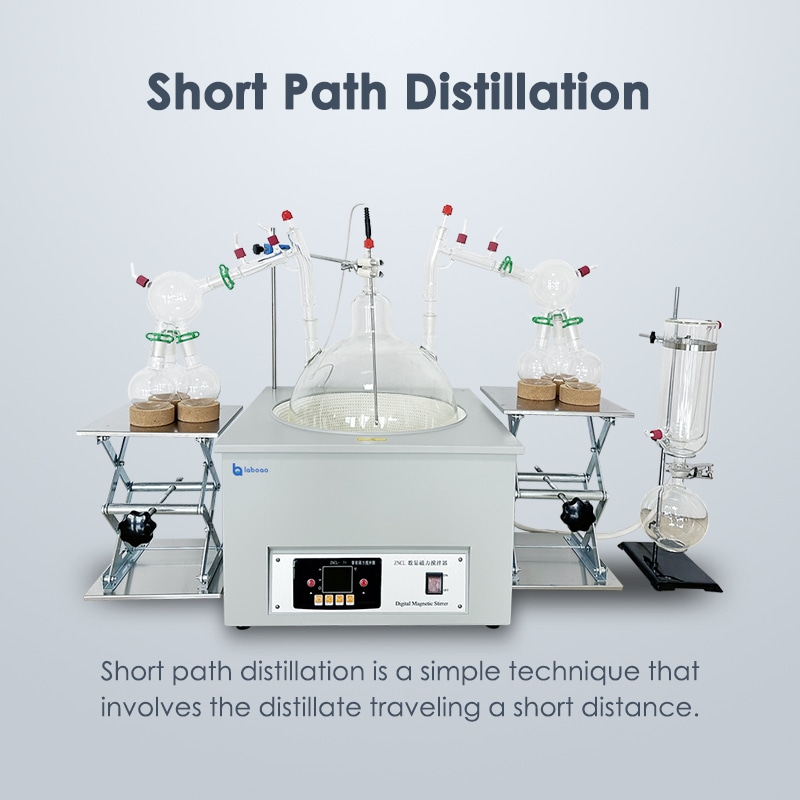

Short Path Distillation

-

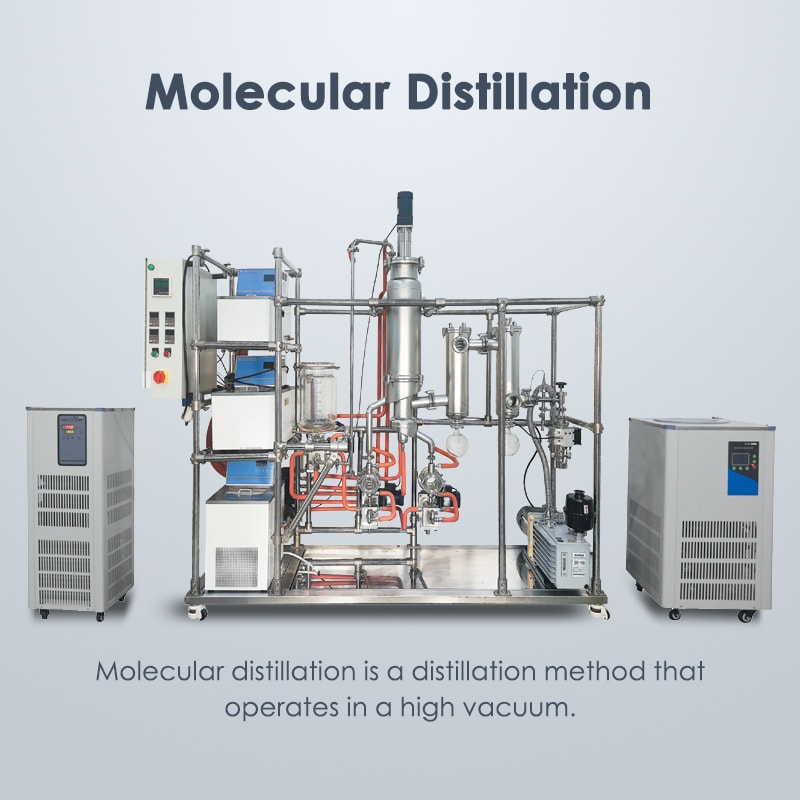

Molecular Distillation

-

Falling Film Evaporator

-

Rotary Evaporator

-

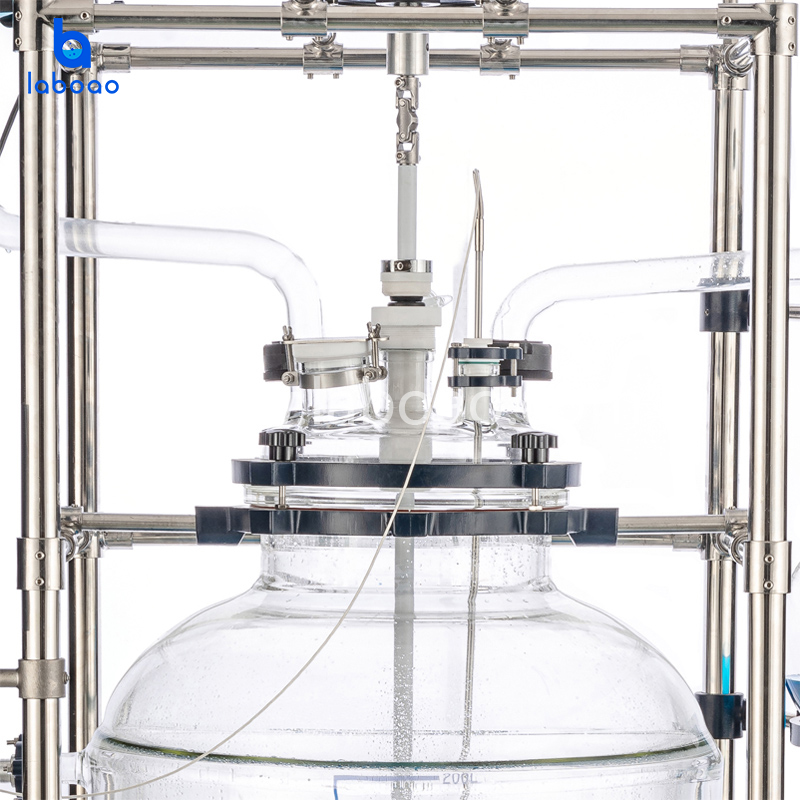

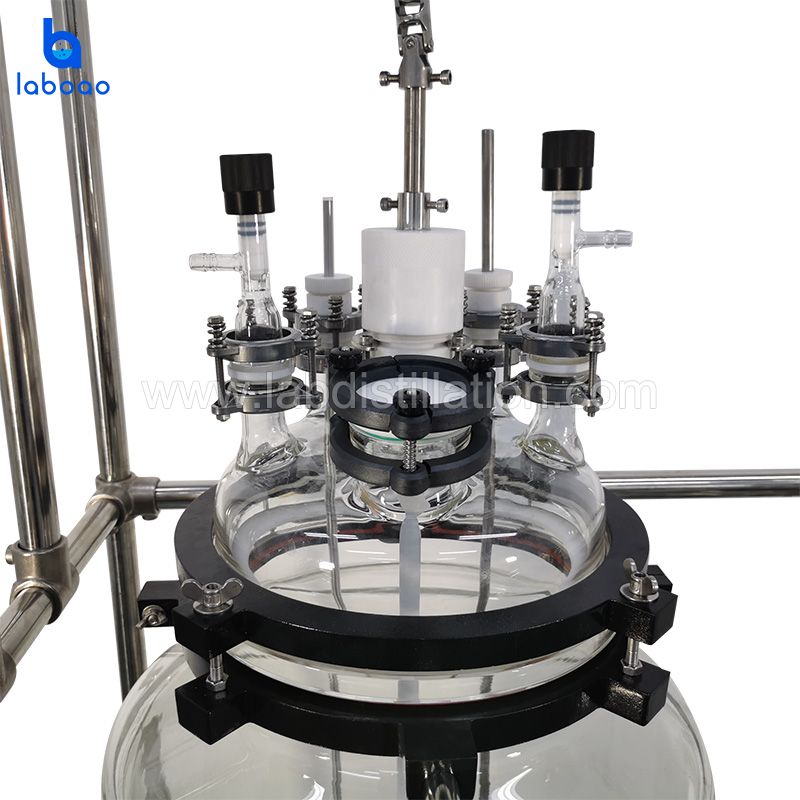

Glass Reactor

-

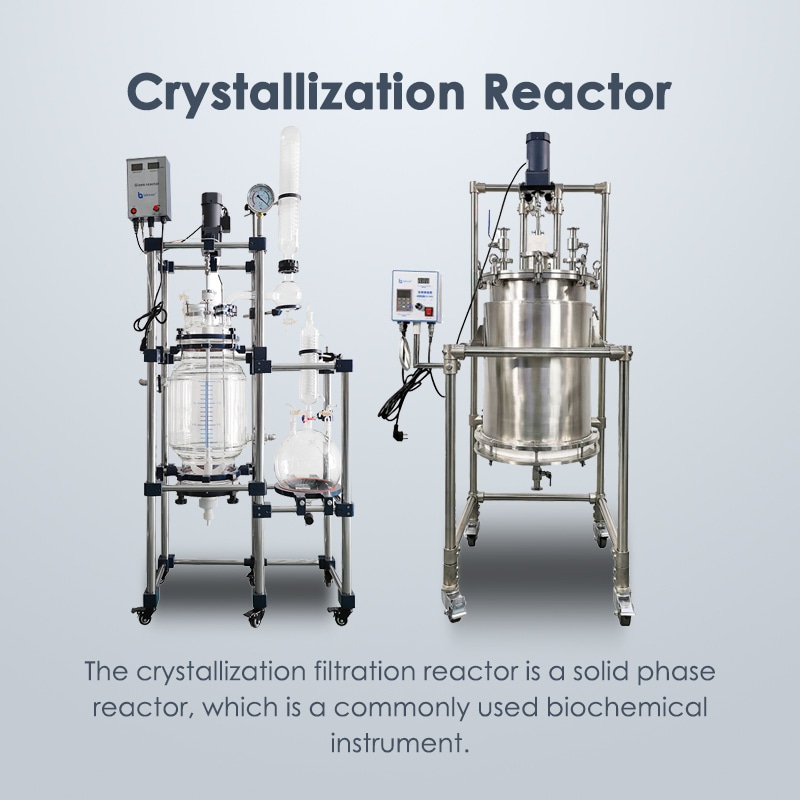

Crystallization Reactor

-

Stainless Steel Reactor

-

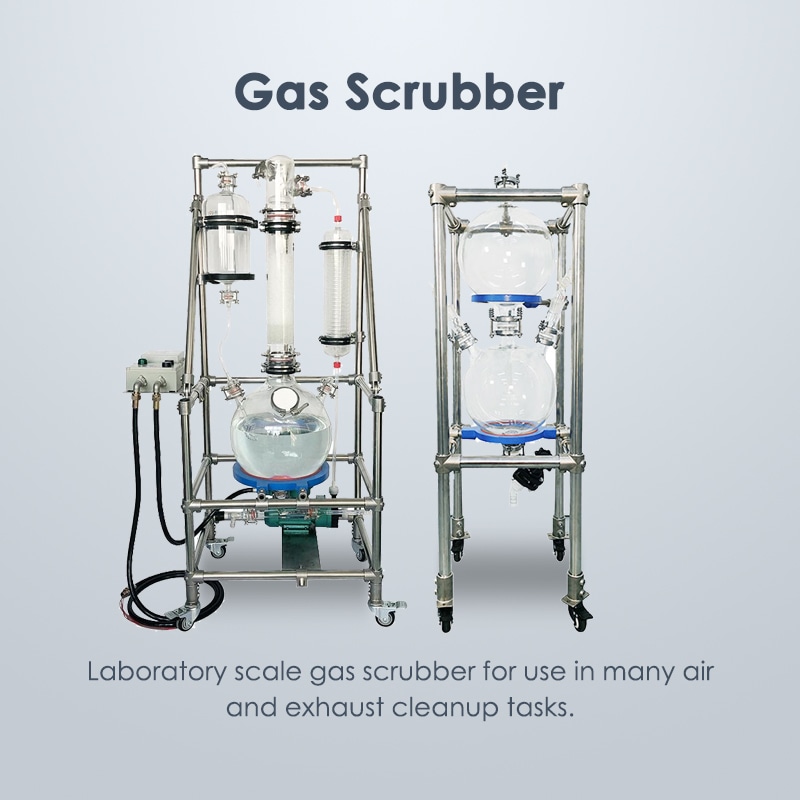

Gas Scrubber

-

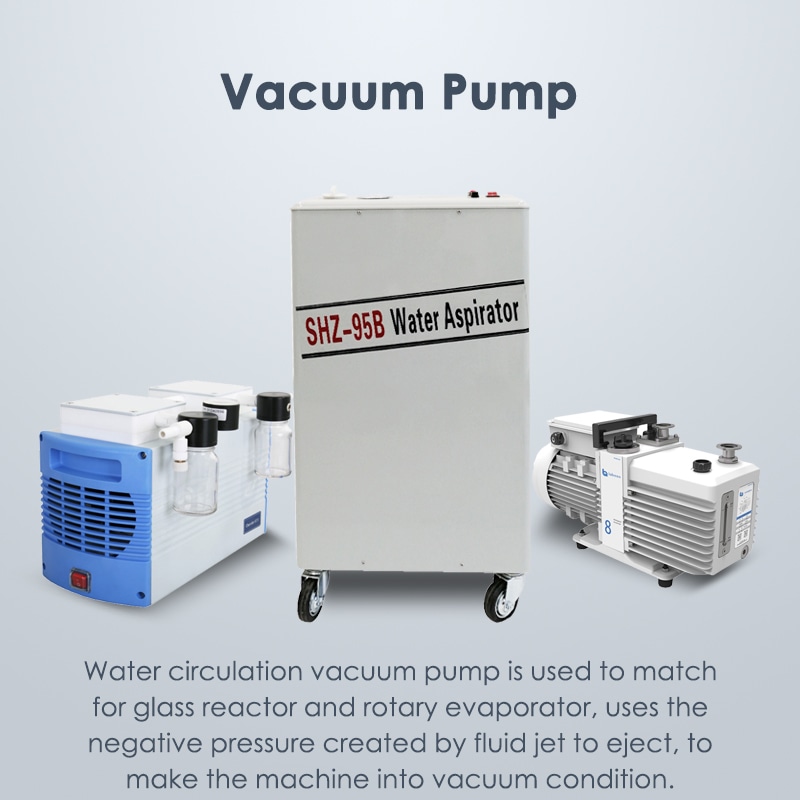

Vacuum Pump

-

Vacuum Filter

-

Glass Liquid Separator

-

Recirculating Chiller

-

Recirculating Heater

-

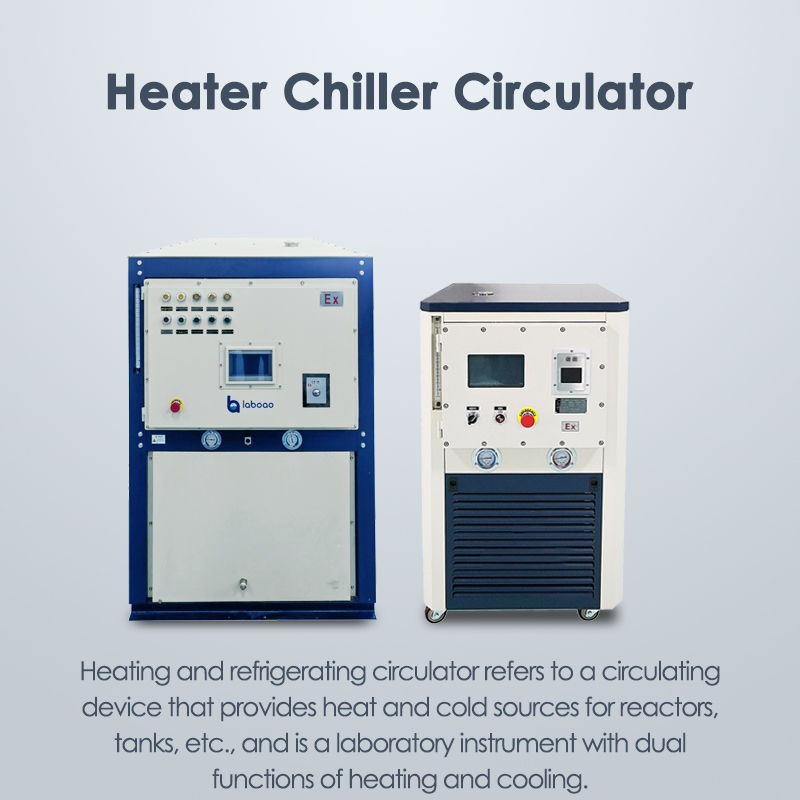

Heater Chiller Circulator

FEATURES PRODUCTS

APPLICATION

ABOUT US

- Quality Assurance

- OEM/ODM

- Can Experiment

Zhengzhou Laboao Instrument Equipment Co., Ltd.(LABOAO) is a manufacturing and sales company with rich experience and passion. We are committed to providing one-stop distillation turnkey solutions.

We specialize in distillation separation technology and have professional technical knowledge in the design and manufacture of distillation processing equipment and services. Viable solutions, reliable quality, and professional services enable us to provide a wide range of applications to customers worldwide. Our engineers are driven by the challenges of this emerging industry, and our entire team is excited to provide great products and solutions.

Our molecular distillation equipment, falling film evaporators, centrifuge extractors, rotary evaporators, glass reactors, etc. work daily in laboratories, universities, R & D departments, large and small companies around the world.

Over the past 10 years, we have always cooperated and communicated with manufacturers with advanced molecular distillation equipment design and manufacturing technology in the world. Our one-stop distillation solution has been widely used and praised in the United States, Canada, Germany, France and other regions.

-

- 15YRS

Extraction Distillation

-

- 130PPL

Research & Design

-

- 20000SQM

Industrial Plant

-

- 7X24HRS

Technical Support

NEWS CENTER

-

User And Maintenance Guide For Low-Temperature Cooling Liquid Circulation Pumps

A low-temperature coolant circulating pump is a core temperature control device that integrates refrigeration, circulation, and constant temperature control. It continuously pumps cooled liquid to external devices and is widely used in laboratories and industrial fields, providing a stable and reliable low-temperature environment for chemical reactors, spectroscopic instruments, vacuum systems, and even medical equipment. -

Double-Layer Glass Reactor User Guide And Key Features

The double-layer glass reactor is a vertical reaction vessel made of high borosilicate glass with a jacketed structure. By circulating a heat transfer medium through the jacket, it can achieve heating, cooling, stirring, reflux, and distillation of materials under normal or negative pressure. It is widely used in fine chemical, pharmaceutical, and scientific research fields. -

The Use Of Rotary Evaporators In Organic Solvent Experiments

A rotary evaporator is a key piece of equipment in chemistry laboratories used for the rapid and gentle concentration or recovery of organic solvents. In organic solvent experiments, it efficiently separates and evaporates volatile organic solvents from less volatile target compounds, and then quickly condenses and recovers them through a condenser, enabling the concentration, purification, or non-destructive recovery of samples or solvents.