FEATURES

1. Frequency control, AC induction motor, speed digital display constant, brushless, no spark, safe and stable, it can work continuously;

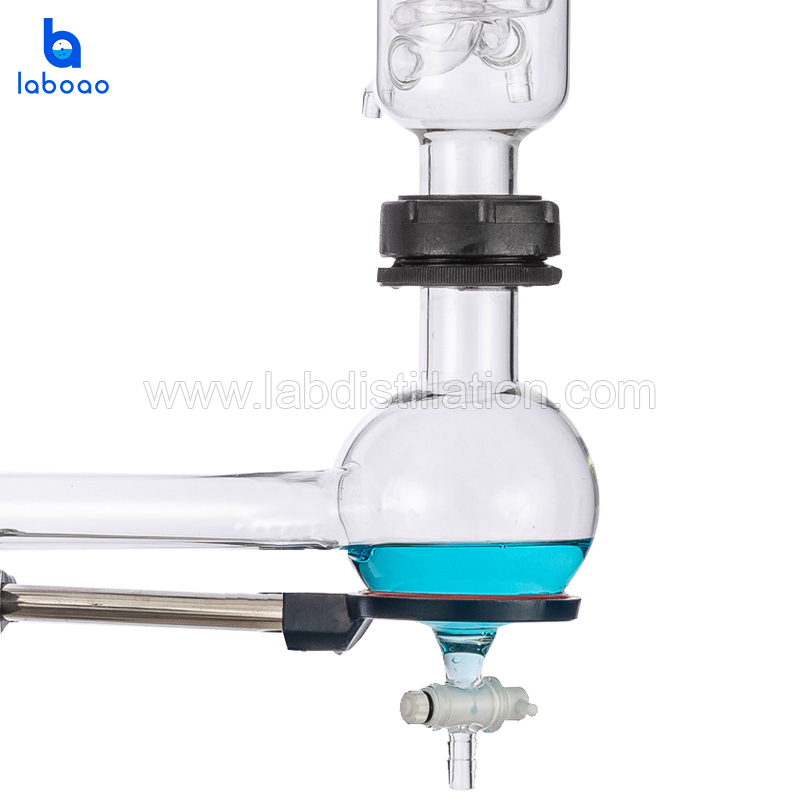

2. Supporting glass using GG3.3 high boron silicon material production, has a good chemical, physical properties; big bottle design, hand out cleaning;

3. PTFE (Ceramic) mechanical component sealing, proprietary technology, it can get the best vacuum degree in the market among the similar products;

4. Overall stainless steel frame structure (foot connecting parts like Tee and four-way valve are all stainless steel), compact and solid, stable and reliable without shaking when mixing;

5. Casters with brake fixed, it is convenient and reliable for mobile use;

6. The PTFE discharge valve without dead corner, solid material/liquid material can be easily released from the bottom;

7. Computer controlled thermostatic oil bath, the intelligent PID control, temperature control is accurate and convenient;

8. Integral structure is scientific design and beautiful appearance, convenient for operation;

9. Explosion-proof series available.

( We can add the cooling coil and an anti-explosion device according to user's needs)