DESCRIPTION

FFE-100 Falling film evaporator is an industrial device to concentrate solutions, especially with heat sensitive components and recover solvents, like ethanol, hexane, heptane, etc. The fluid will create a film along the tube walls, progressing downwards (falling) - hence the name. It is specifically suited to process the products with a low viscosity and a low tendency for fouling.

In general the evaporation takes place inside the vertical tubes, which is called shell-and-tube heat exchanger, crowned by a proprietary liquid distribution device. The fluid distributor is designed carefully in order to ensures an efficient and uniform distribution of the liquid to all the tubes along which the product flows as a continuous film falls, driven by gravity.

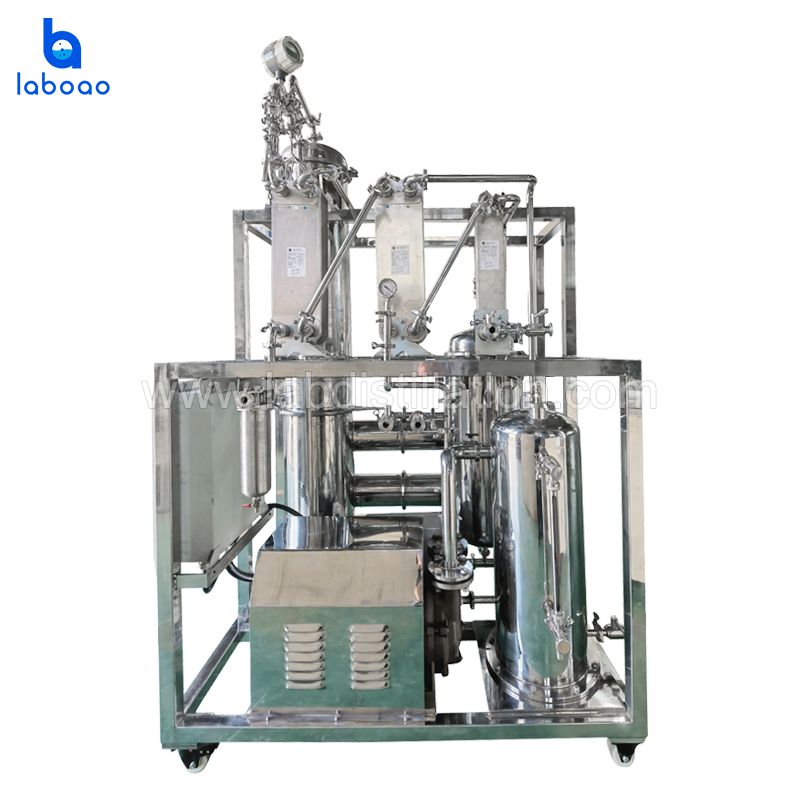

The whole solvent recovery system not only includes falling film evaporator, but also equips circulation heater (steam generator as an option), water cooling tower, circulation chiller, vacuum pump and all accessories.