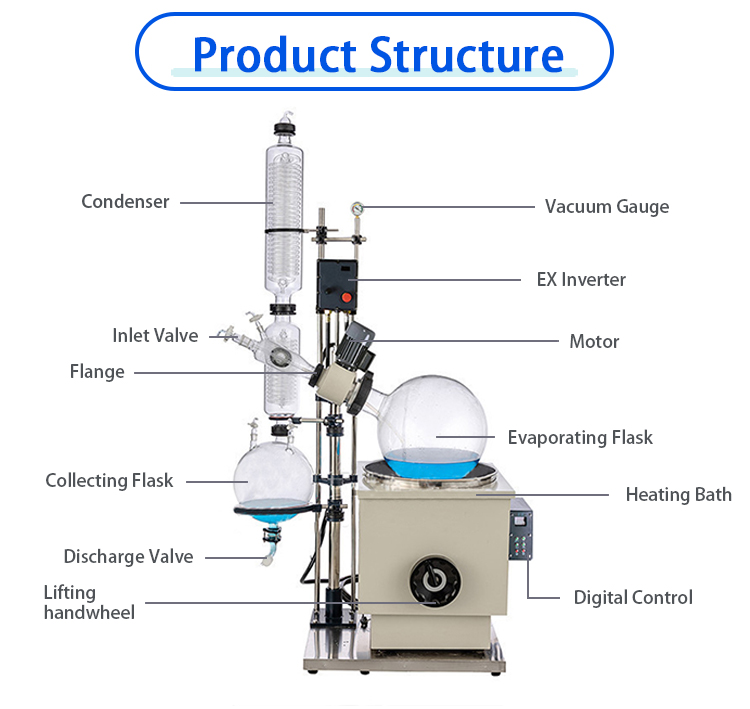

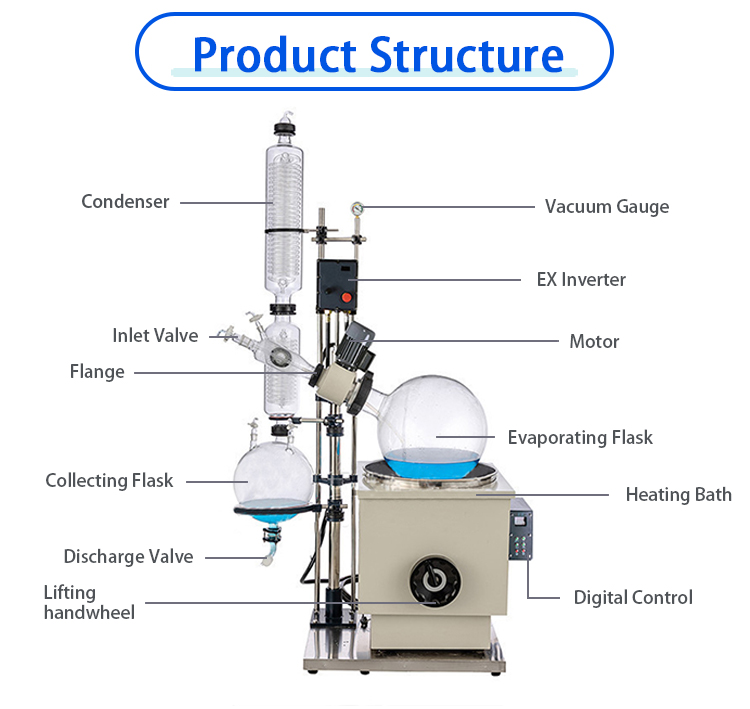

DESCRIPTION

The explosion-proof rotary evaporator is mainly used for concentration, crystallization, drying, separation and solvent recovery in the pharmaceutical, chemical and biopharmaceutical industries. The principle is to heat the rotating bottle at a constant speed under vacuum conditions, and the material forms a large-area film on the bottle wall, which evaporates efficiently. The solvent vapor is cooled by a high-efficiency glass condenser and recovered in the collection bottle, which greatly improves the evaporation efficiency. It is especially suitable for the concentration and purification of biological products that are easily decomposed and denatured at high temperature.

FEATURES

1. All of the high boric silicon glass (expansion coefficient 3.3) and polytetrafluoride material are all used in contact with the material contact portion, and the performance is stable, and it is not easy to chemically react with materials.

2. The main bracket uses cold plate anti-corrosion spray + aluminum alloy material, and has strong anti-corrosion characteristics. Pot bile adopts stainless steel quality, compact structure, durable, beautiful appearance;

3. The sealing system uses the polytetrafluoroethylene + fluororubber combination seal to maintain high vacuum;

4. Vacuum pressure gauge display real-time vacuum, pointer display;

5. The piston feeding valve sleeve piratifores lengthen tubes, which can be continuously fed to evaporation bottles in a vacuum state, which is convenient for customers.

6. Integrated condenser, upright double-layer snake-shaped coil to ensure high recovery;

7. Variable frequency speed, explosion-proof switch. The knob is fine-tuning, the number of revolutions is displayed;

8. Constant temperature bath temperature digital display, K-type sensor + stainless steel probe, fast transmission temperature

9. Bath pot hand wheel rises, easy to operate;

10. Electric explosion-proof, variable frequency speed aluminum shell explosion-proof, control plate aluminum shell explosion-proof, cable wear explosion pipe.

SPECIFICATIONS

Model | LRE-1002EX | LRE-2002EX | LRE-5002EX |

Voltage/Frequency | 220V/50HZ | 220V/50HZ | Rotation 220V/50HZ; Heating pot 380V/50HZ |

Whole power | 3120W | 5120W | 8180W |

Rotary power | EX120W | EX120W | EX180W |

Heating power | 3000W | 5000W | 8000W |

Vacuum degree | 0.0095Mpa | 0.0095Mpa | 0.0095Mpa |

Rotary flask volume | 10L Φ280mm/Φ95 flange port | 20L Φ355mm/Φ95 flange port | 50L Φ470mm/Φ125 flange port |

Receiving flask volume | 5L Φ230mm/ upper with Φ60 flange port*24# standard port* down with Φ50 flange port | 10L Φ280mm/ upper with Φ60 flange port *24# standard port* down with Φ50 flange port | 20L Φ355mm/ upper with Φ60 flange port *24# standard port* down with tΦ50 flange port |

Rotary speed | 0-120rpm/min | 0-120rpm/min | 0-120rpm/min |

Temp.cotrolling range | room temperature -180℃ | room temperature -180℃ | room temperature -180℃ |

Temp. accuracy | ±1℃ | ±1℃ | ±1℃ |

Flask lifting distance | 180mm | 180mm | 180mm |

Condenser size | The main condensor Φ120*620H(mm) ,upper with Φ60 flange port* down with Φ80 flange port

The assisted condensor Φ135*475H(mm) , upper with Φ80 standard port * down with Φ60 flange port* side with Φ60 flange port | The main condensor Φ130*700H(mm) , upper with Φ60 flange prot* down with Φ80 flange port

The assited condensor Φ160*530H(mm) ,upper with Φ80 flange port * down with Φ60 flange port* side with Φ60 flange port | The main condensor Φ160*835H(mm) ,upper with Φ60 flange port* down with Φ80 flange port

The assisted condensor Φ160*530H(mm) ,upper with Φ80 flange port* down with Φ60 flange port*side with Φ60 flange port |

Condensation area | 0.51(0.33+0.18)㎡ | 0.95(0.46+0.49)㎡ | 1.44(0.95+0.49)㎡ |

Air guide bottle | left with Φ34 standar port , upper with 19# standard port, side with Φ60 flange port, right with Φ60 flange port | left with Φ34 standar port , upper with 19# standard port, side with Φ60 flange port, right with Φ60 flange port | left with Φ40 standard port, upper with 19# standard port, side with Φ60 flange port, right with Φ70 flange port |

Charging valve | 34# standard plug valve, feed nozzle ( Pagoda-shape connectors), outer diameter 12mm | 34# standard plug valve, feed nozzle ( Pagoda-shape connectors), outer diameter 12mm | 40# standard plug valve, feed nozzle ( Pagoda-shape connectors), outer diameter 12mm |

Multi-function port | 19# standard plug valve, glass nozzle (Pagoda-shape connectors), outer diameter 12mm | 19# standard plug valve, glass nozzle (Pagoda-shape connectors), outer diameter 12mm | 19# standard plug valve, glass nozzle (Pagoda-shape connectors), outer diameter 12mm |

Vacuum suction nozzle | Φ60 flange glass exhaustor, suction nozzle (Pagoda-shape connectors), outer diameter 10mm | Φ60 flange glass exhaustor, suction nozzle (Pagoda-shape connectors), outer diameter 10mm | Φ60 flange glass exhaustor, suction nozzle (Pagoda-shape connectors), outer diameter 10mm |

Condensing coil in and out circuation nozzle | Pagoda-shape connectors, outer diameter 16mm | Pagoda-shape connectors, outer diameter 16mm | Pagoda-shape connectors, outer diameter 16mm |

Vent valve | 24# standard plug valve*2 vent nozzle(Pagoda-shape connectors), outer diameter 12mm | 24# standard plug valve*2 vent nozzle(Pagoda-shape connectors), outer diameter 12mm | 24# standard plug valve*2 vent nozzle(Pagoda-shape connectors), outer diameter 12mm |

Baiting valve | Φ50 flange port,Side discharging nozzle (pagoda-shape connectors), outer diameter 20mm, 200 from the floor | Φ50 flange port,Side discharging nozzle (pagoda-shape connectors), outer diameter 20mm, 200 from the floor | Φ50 flange port,Side discharging nozzle (pagoda-shape connectors), outer diameter 20mm, 320 from the floor |

Pot bravery size | Φ350*220H(mm) about 21L | Φ450*260H(mm) about 41L | Φ550*320H(mm) about 76L |

Overall dimensions (W*L*H) | 930*560*1910mm | 1000*600*2130mm | 1330*730*2340mm |

Net weight | 83kg(52.5+30.5) | 97kg(60.5+36.5) | 128kg(85.5+42.5) |

Packing dimensions | 1320*780*755mm, 0.78m³ | 1350*670*720mm; 680*680*790mm,1.02m³ | 1420*820*720mm; 830*730*910mm, 1.39m³ |

Packing weight | 116kg | 143kg(88+55) | 195kg(103+92)

|