At present, research institutions and production companies at home and abroad are accelerating the industrialization process of CBD. Their goals are: while improving the extraction rate and purity of CBD, remove THC residues as much as possible, avoid the use of toxic organic solvents as much as possible, to ensure the safety and environmental protection of the product, and reduce costs as much as possible.

Rough extraction - Common industrial hemp CBD extraction technologies include carbon dioxide extraction and solvent extraction:

1. Supercritical carbon dioxide extraction method

Supercritical carbon dioxide extraction is the most commonly used plant extraction method.

(1) The temperature of carbon dioxide is reduced to below -56.1 ℃ and the pressure is increased to above 0.52 MPa through a compression device. At this time, carbon dioxide gas is converted into liquid. Increase the temperature and pressure until the liquid becomes "supercritical".

(2) Place high-quality cannabis in the extractor, and supercritical carbon dioxide dissolves in the extractor and collects the plant extract. Send the liquid carbon dioxide into the low-pressure separator, and the cannabis extract will be automatically separated from the carbon dioxide.

(3) After the carbon dioxide reaches the supercritical state after passing through the compression device, it continues to return to the extraction tank for cannabis extraction until the extraction is completed. The carbon dioxide returns to the storage tank, and the CBD crude product flows out of the separator and is collected in the storage tank.

2. Solvent extraction method

Usually, ethanol is used as a solvent to extract CBD oil from cannabis plants. This process is complicated, with many operating steps, and a large amount of ethanol is used, which has flammable and explosive safety hazards.

CBD crude product purification and refining process

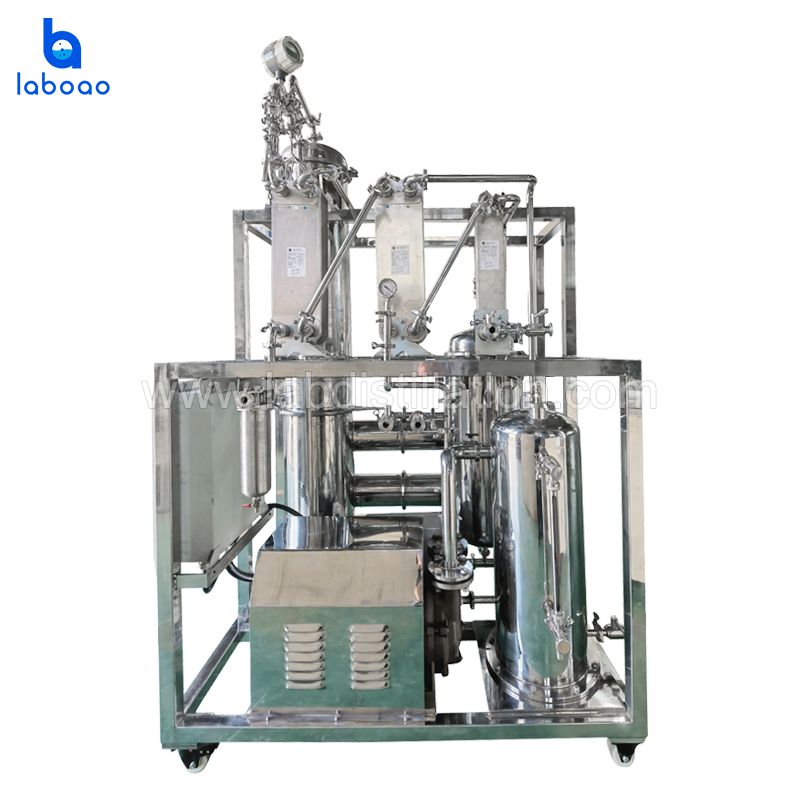

1. Molecular distillation

Molecular distillation can effectively remove the solvent in the extract, and play a role in decolorization, removing chemical residues and harmful metal components. The purity of CBD crude products after molecular distillation can be increased to more than 70%.

2. Resin adsorption

(1) Column chromatography: This method is characterized by the use of many columns for chromatography and a long loading time. To obtain high-purity CBD, repeated loading is required. Sometimes the purity still does not meet the requirements and recrystallization is required.

(2) Ion exchange method: Using macroporous resin for enrichment and purification, this method requires repeated crystallization and concentration. The loss of each crystallization is about 5%, which is very serious for products with high added value.

(3) Chromatographic column separation method: This method uses the separation principle of ordinary liquid chromatography, based on a large-diameter liquid chromatography column and a large-volume liquid delivery system. By optimizing the stability, distribution and ratio of the elution solvent of the fluid, the separation efficiency and separation effect of the target product can reach a high level. This method can be used to separate crude CBD and extract all monomers in cannabinoids according to needs, such as CBD, CBG, CBN, CBC, etc. The purity of the separated CBD product can be as high as 97% or more.

At present, molecular distillation + chromatographic column separation is mostly used in engineering applications to separate and purify CBD crude products. It can continuously feed and discharge, isocratically elute, and purify by rolling multiple columns. It can solve products that are difficult to separate. The concentration of the obtained product is similar to the injection concentration, which greatly reduces the amount of solvent concentration.

The process of CBD extraction and purification can be flexibly selected and adjusted according to the characteristics of the end product, the content of the active ingredients of the raw materials, the investment intensity of the construction party, etc., to produce CBD raw materials with different needs. With the continuous upgrading of technology, it is believed that more advanced processes will be added to the CBD industry to help the development of the CBD industry.