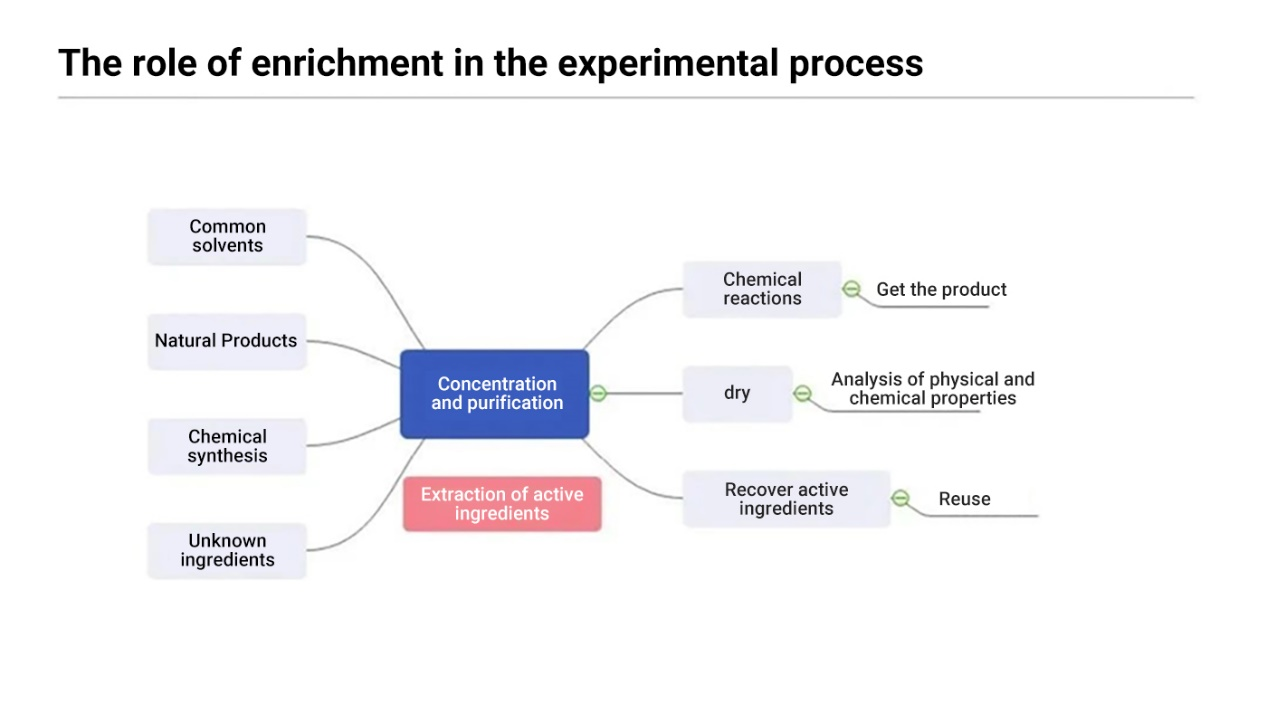

1. Refining and concentration of Chinese medicine preparations

The rotary evaporator is particularly suitable for the refining and concentration of Chinese medicine preparations that are easily decomposed and denatured when exposed to high temperatures. Such as the extraction of natural products and drug synthesis experiments, such as the extraction of rutin. In this process, it is necessary to soak the Sophora japonica seeds in ethanol, and the extract is evaporated by the rotary evaporator to obtain the rutin extract.

2. Concentration of Chinese medicine extracts

The concentration of Chinese medicine extracts is a typical application of the rotary evaporator. The heating tank of the rotary evaporator is used to heat the solution to vaporize it, and the steam is condensed by the condenser to remove part of the extraction reagent, thereby increasing the concentration of the solute in the solution. In the pretreatment process of Chinese medicine preparations, the medicinal materials are mostly extracted with purified water or a certain concentration of ethanol. For example, the process of preparing licorice extract, rhubarb extract, angelica extract, etc. can use the rotary evaporator to recover the solvent.

3. Molecular cocktail making

The basic method of molecular cocktail making is to use a rotary evaporator to prepare the cocktail components. The rotary evaporator can distill ethanol at room temperature to extract natural ingredients from fruits, petals or other ingredients to adjust the aroma, taste and color of the cocktail. Because all extraction processes are carried out at room temperature, the color, aroma and taste of various natural ingredients are retained to the maximum extent without being destroyed.

4. Recycling oil solvents

The rotary evaporator can be used to recover oil solvents, such as removing a large amount of ethanol from cannabis oil and solvent extraction of chicken fat. It uses the "large amount of evaporation" of solutes and solvents, the temperature difference is large, and the required temperature of the solvent is very low, which can be satisfied by a water bath. After the solvent is separated, it is in a gaseous state, and the average molecular weight is greater than that of air. The separation of solutes and solvents will obtain the characteristics of the target fat, and the recovery of solvents is also beneficial to the environment and is a manifestation of reuse.

5. Chemistry and pharmaceuticals

It is used for solvent removal and product purification in organic synthesis, especially the low-temperature concentration of heat-sensitive substances to avoid decomposition caused by high temperature.

In the research and development of pharmaceutical preparations, it is used for extract concentration and solvent recovery to improve drug purity.

6. Food industry

Concentrate food additives such as fruit juice and flavorings to increase product flavor concentration.

Separate solvents (such as ethanol) when extracting oils and fats to achieve environmentally friendly solvent recycling.

7. Environmental protection and wastewater treatment

By concentrating pollutants (such as heavy metals and organic solvents) in waste liquids, reduce wastewater discharge and recover useful substances.

8. Petrochemical industry

In the field of petrochemicals, rotary evaporators can be used for distillation of impurity components, such as separation and concentration of toxic gases such as hydrogen sulfide contained in petroleum. It helps to improve the quality of petroleum products and reduce environmental pollution.